In the ever-evolving landscape of electronic devices, managing heat dissipation effectively is crucial to ensuring longevity and optimal performance. As devices become more powerful and compact, the challenge of maintaining an ideal operating temperature intensifies. This is where advanced tungsten copper heat sink technology comes into play, offering a promising solution to enhance device lifespan.

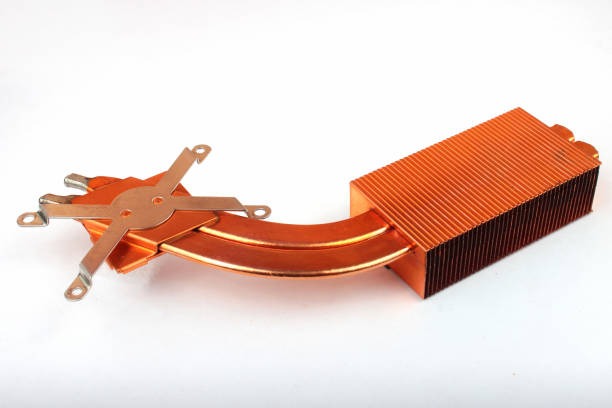

Tungsten copper heat sinks are gaining attention due to their exceptional thermal management properties. These materials combine the high thermal conductivity of copper with the low coefficient of thermal expansion of tungsten, resulting in a composite that excels in dissipating heat efficiently while maintaining structural integrity under varying temperatures. This unique combination addresses two critical aspects: effective heat dispersion and mechanical stability.

One of the primary benefits of tungsten copper heat sinks is their ability to manage higher power densities without compromising on size or weight. In modern electronics, where space is at a premium, this feature becomes invaluable. Devices can operate at higher speeds and capacities without overheating risks, thereby extending their operational life significantly.

Moreover, tungsten copper’s superior thermal conductivity ensures rapid transfer and dispersal of generated heat away from sensitive components. By minimizing hot spots within devices, these advanced heat sinks reduce stress-induced wear on internal https://amt-mat.com/understanding-tungsten-copper-heat-sinks/ parts—a common cause for premature failure in electronics. The result is not only enhanced durability but also improved reliability over extended periods.

Another advantage lies in tungsten copper’s adaptability across various applications—from consumer electronics like smartphones and laptops to industrial machinery and aerospace systems. Its versatility makes it an ideal choice for manufacturers seeking universal solutions for diverse technological needs.

Furthermore, incorporating tungsten copper technology aligns with sustainability goals by reducing electronic waste through prolonged device lifespans. Longer-lasting products decrease the frequency of replacements required by consumers—an environmentally conscious approach that resonates with both manufacturers aiming for greener practices and users advocating for sustainable consumption patterns.

However, despite its numerous advantages, widespread adoption faces challenges primarily related to cost implications associated with material procurement and processing techniques involved in manufacturing these sophisticated composites. Nevertheless, ongoing research aims at optimizing production methods which could eventually make this technology more accessible across different market segments.

In conclusion, as we advance towards increasingly complex electronic architectures demanding efficient thermal management solutions; leveraging innovative materials like tungsten-copper composites presents significant opportunities not just for enhancing device performance but also promoting longer product lifecycles—a win-win scenario benefiting both industry stakeholders committed towards innovation-driven growth strategies alongside end-users prioritizing value retention over time amidst rapid technological advancements shaping our world today.